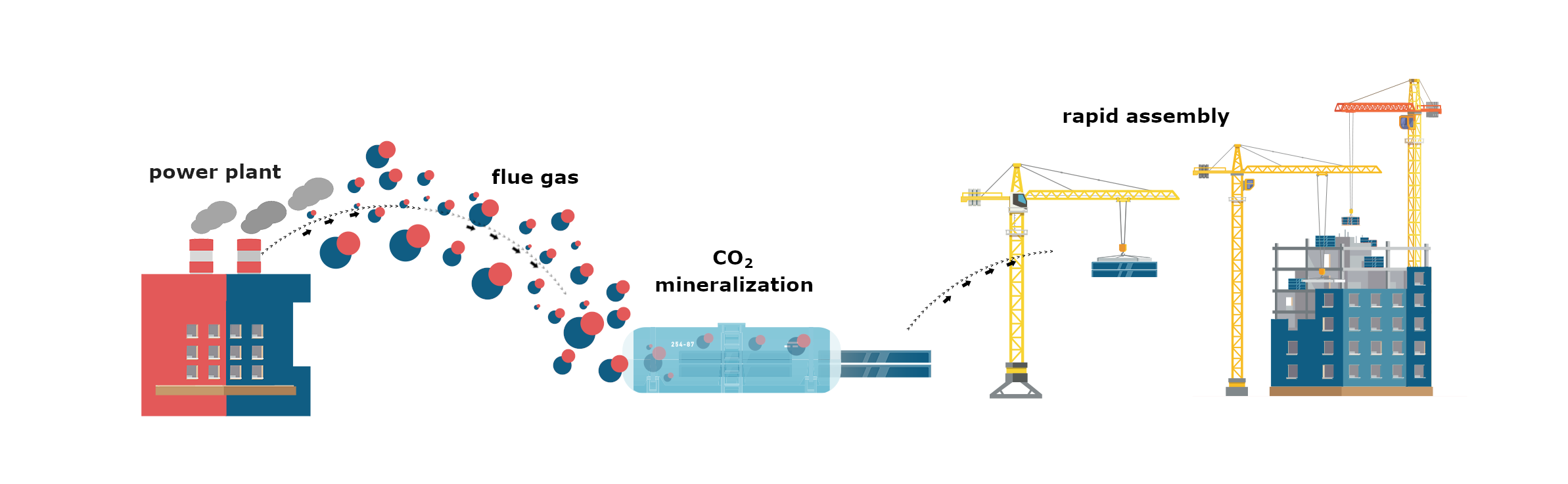

The CO2Concrete technology turns carbon dioxide emissions into CO2Concrete™ products that can replace traditional concrete, with a much lower CO2 footprint. The technology is based on the concept of “CO2 mineralization” – the conversion of gaseous CO2 into solid mineral carbonates (e.g., CaCO3) within the CO2Concrete™ products.

Carbon Capture Process

This chemical reaction is robust, and strengthens the fresh CO2Concrete™ products into components exceeding industry standard performance metrics. Key advantages of the technology include the following:

- Direct utilization of CO2 from flue gases without a need for carbon capture systems (e.g., amine strippers)

- Process flexibility to accommodate flue gas streams with widely varying CO2 concentrations, and presence of acid gases

- Process operates at ambient pressure and temperature, minimizing extrinsic energy requirements

- Material formulation requires no ordinary portland cement (OPC) to exceed industry standards for component performance